Advanced technology behind Nobel Prize in Physics

Supporting blue LED development through “measurement” technology

(Published on December 19, 2018)

Blue LED was believed to be impossible to develop in the 20th century

LED lights are now widely used at home instead of incandescent and fluorescent lamps. However, LED for lighting that emits white light could not have been realized without blue LED.

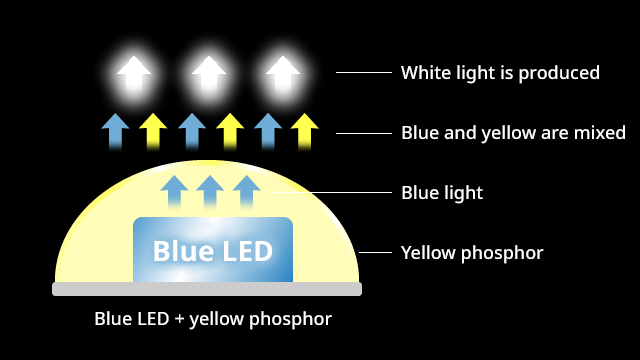

In the early 1960s, red LED was commercialized for the first time, followed by yellow-green LED. However, the development of blue LED was extremely difficult and was believed to be impossible to complete in the 20th century. Light has different energy levels, depending on the color. Blue light has higher energy than red light. Only by combining yellow phosphor with blue LED that emits light with high energy, white light sources with high brightness and low power consumption can be produced at low cost. This point was an important consideration in the awarding of the Nobel Prize in Physics. And the realization of blue LED has brought many benefits to our lives.

Blue light and yellow light are mixed to become white light.

Blue light and yellow light are mixed to become white light.

Mechanism of white light

Semiconductor test systems of TOYO Corporation contributed to the development of blue LED

Prof. AKASAKI, Prof. AMANO and Prof. NAKAMURA who made the major achievement all used a measurement system called “ResiTest (Footnote 1),” a Hall effect measurement system (a kind of semiconductor test system) developed by TOYO Corporation.

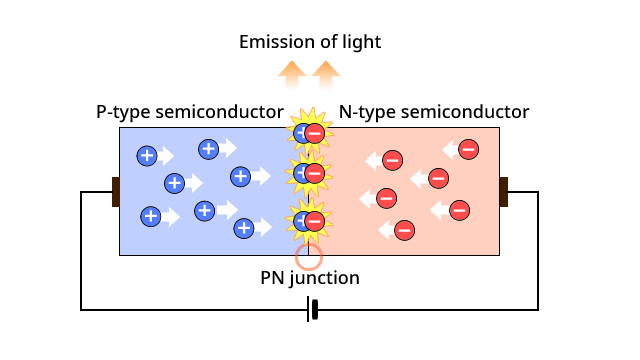

LED is made of semiconductor. Electrons (electricity) flow through the semiconductor, transforming electric energy into light energy. The energy level of light emitted from the semiconductor is determined by the types of elements that comprise the semiconductor and the crystal structure. In other words, the color of light emitted from the semiconductor depends on the level of the light energy.

The development of blue LED was hindered by the difficulty of manufacturing semiconductor that emits blue light with a high energy level. The ResiTest system can measure the number of electrons inside the semiconductor, the speed of their movement and the energy level, which determine the quality of the semiconductor, two orders of magnitude more precisely than previous measurement instruments. Accurate measurements of invisible movements of electrons accelerated the development cycle of new semiconductors and played a major role in the development of semiconductors that emit blue light.

Footnote 1: ResiTest is a Hall measurement system in which the noise removal technology by AC magnetic field developed by TOYO Corporation improved the measurement sensitivity by more than 100 times compared to the past.

When a voltage is applied in the forward direction, electrons move, and light is emitted.

When a voltage is applied in the forward direction, electrons move, and light is emitted.

Mechanism of light emission of LED

History of the development of the “ResiTest” semiconductor measurement system

In the 1980s, some candidates had already been identified for the types of elements and crystal structures for semiconductors that emit blue light, but there was no established method for manufacturing high-quality crystals. Therefore, scientists used a solid but very time-consuming method of creating a prototype, measuring it, evaluating the quality, and making further improvements for another prototype. Even though this method required accurate measurements of the quality of the prototype semiconductor, such measurements could not be realized satisfactorily at that time. Although the idea of using Hall effect measurements to measure the quality of semiconductors already existed, the "Hall effect signals" were so small that it was difficult to measure them with a measurement instrument at the early stage of development because of large noise. TOYO Corporation devised an "AC Hall measurement method (Footnote 2)" that can remove this noise and measure small Hall effect signals, and successfully developed a Hall effect measurement system "ResiTest" which is useful for evaluation tests of semiconductors for blue LED.

Footnote 2: This technology is patented by TOYO Corporation under the title “Hall effect measurement system and its procedures.”

“ResiTest” Hall effect measurement system that supported the R&D efforts of the three professors

“ResiTest” Hall effect measurement system that supported the R&D efforts of the three professors

Advancing with the cutting-edge R&D

The AC Hall measurement method, the core of the ResiTest system, was created in our unique environment where the world's most advanced measurement instruments are available anytime. Above all, it was a very valuable experience for us to be able to share the challenges of and to be inspired by the innovative researchers who would later receive the Nobel Prize. The driving force behind our innovation was the strong desire to “provide support somehow” when the R&D efforts of such passionate researchers hit a technological obstacle.

TOYO Corporation will continue to assist researchers and developers with our latest “measurement technologies.”